(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 9:00 24/11/2024 to 7:00 (MYT) 25/11/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- Please note that E-Invoice will be sent to our customers by email. For more information, please read News.

Oil Free Bushing Housing Units Round Flanged

- Volume Discount

- Oil Free Bushing Housing Units Round Flanged C-MFM series from MISUMI.

- Upgraded Economy Series Oilless Bushing Unit with technical enhancements.

- The case material changed from stainless steel to lightweight aluminum alloy.

- Oilless bushing material upgraded to a durable bronze alloy.

- Integrated one-piece design ensures even distribution of solid lubricant.

- Improved lubrication performance and significantly reduced noise

- Recommended for vertical motion applications.

- Easy installation and lower maintenance frequency

- Upgrade your equipment for smoother operations and enhanced durability.

Part Number

Configured Part Number is shown.

Economy Oil Free Bushing Round Flanged

- The oilless bushing integrates solid lubricant throughout the bronze alloy, ensuring even distribution and significantly improved lubrication performance

- The case material is changed from stainless steel to lightweight aluminum alloy, offering the same strength but with reduced weight, enhancing overall performance

- Enhanced design and materials result in significantly reduced noise levels during operation, making it ideal for environments where noise reduction is crucial

- Upgraded from high-strength brass to durable bronze alloy, providing better wear resistance and longer service life

- Advanced lubrication and durable materials ensure a longer service life, reducing the frequency of replacements and maintenance

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

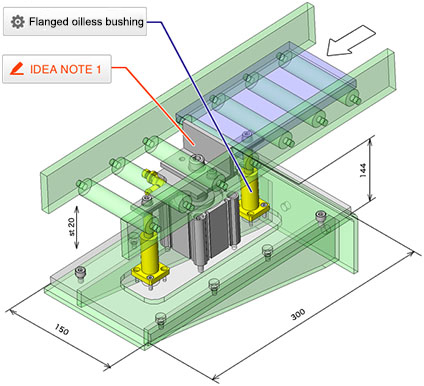

Oil Free Bushings Product Overview

The oilless bushing is no longer embedded in a hole but integrated as one piece, ensuring more evenly distributed solid lubricant

, improved lubrication performance and significantly reduced noise.

This product is recommended for motions in the vertical direction, allowing easy installation and low maintenance frequency.

Oil Free Bushings Product Features

1. It is the first time MISUMI has integrated oilless bushing in copper plate, with the assistance of strong glue, allowing the bushing and aluminum alloy case to be tightly press-fitted (patent pending). Compared with the ordinary solid lubricant embedded product, the new solid lubricant is distributed more evenly and the lubricating area is increased by 20%, lubrication effect of oil free bushing greatly improved.

2. Longer service life due to improved lubrication

Conventional type: Final wear amount of 0.030 mm

New product: Final wear amount of 0.020 mm

Experiment conditions: Surface pressure of 25 N/mm2, swing speed of 1 m/min, swing frequency of 96,000 times, experiment time of 100 h

Conventional type

New Products

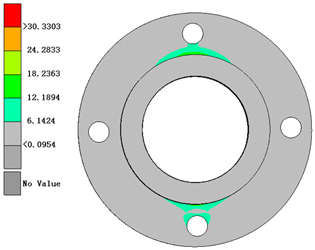

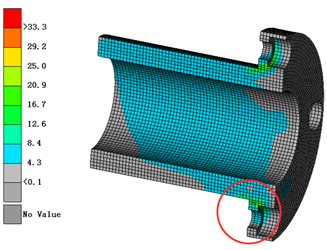

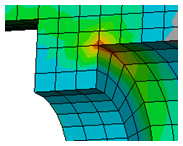

Test demonstration: Analysis result of 0.1 mm forced shift of guide shaft in Y direction after the oilless bushing is fixed with screws.

| Material | Yield Strength | Stress concentration result |

| Aluminum Alloy A6061 | 240Mpa | 30.3Mpa |

| Steel SS400 | 235Mpa | 42.5Mpa |

| Stripping test | |

| Circlip fixed product | New Products |

| 1.73Mpa | 2.45Mpa |

Oil Free Bushings Dimensional Drawing

Case material: Aluminum alloy A6061

Surface treatment: Passivation treatment

Liner material: Bronze alloy

* Passivation is a method of treatment to generate a passivation film through direct reaction between aluminum alloy and chemical solution, thereby improving corrosion resistance and bonding force

| Part Number | d | D | L | L1 | H | T | d1 | d2 | t | P.C.D | W | F | A | |||||

| Type | Tolerance | Tolerance | Short | Long | ||||||||||||||

| Round Flanged C-MFM | Square Flanged C-MFK | Flanged type C-MFN | 10 | +0.028 0 | 19 | 0 -0.018 | 32 | 57 | 5 | 40 | 6 | 4.5 | 7.5 | 4.1 | 29 | 30 | - | 29 |

| 12 | +0.034 0 | 21 | 0 -0.021 | 32 | 57 | 10 | 42 | 32 | 32 | - | 32 | |||||||

| 16 | 28 | 37 | 67 | 48 | 38 | 37 | 22 | 31 | ||||||||||

| 20 | +0.041 0 | 32 | 0 -0.025 | 42 | 77 | 54 | 8 | 5.5 | 9 | 5.1 | 43 | 42 | 24 | 36 | ||||

| 25 | 40 | 58 | 108 | 62 | 51 | 50 | 32 | 40 | ||||||||||

| 30 | 45 | 68 | 128 | 74 | 10 | 6.6 | 11 | 6.1 | 60 | 58 | 35 | 49 | ||||||

| 40 | +0.050 0 | 60 | 0 -0.030 | 80 | 150 | 15 | 96 | 13 | 9 | 14 | 8.1 | 78 | 75 | 50 | 60 | |||

| 50 | 80 | 90 | 170 | 116 | 98 | 92 | 58 | 80 | ||||||||||

Oil Free Bushings Usage Method

Oil Free Bushings Specifications Overview

Oil Free Bushings Example of Use

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

| Part Number |

|---|

| C-MFM10-32 |

| C-MFM10-57 |

| C-MFM12-32 |

| C-MFM12-57 |

| C-MFM16-37 |

| C-MFM16-67 |

| C-MFM20-42 |

| C-MFM20-77 |

| C-MFM25-58 |

| C-MFM25-108 |

| C-MFM30-68 |

| C-MFM30-128 |

| C-MFM40-80 |

| C-MFM40-150 |

| C-MFM50-90 |

| C-MFM50-170 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Inner Dia. d (Ø) | Outer Dia. D (Ø) | Overall Length L (mm) |

|---|---|---|---|---|---|---|---|

MYR 55.58 | 2 Piece(s) | Available | 10 Day(s) | 10 | 19 | 32 | |

MYR 108.38 | 2 Piece(s) | Available | 10 Day(s) | 10 | 19 | 57 | |

MYR 58.06 | 2 Piece(s) | Available | 10 Day(s) | 12 | 21 | 32 | |

MYR 115.00 | 2 Piece(s) | Available | 10 Day(s) | 12 | 21 | 57 | |

MYR 64.40 | 1 Piece(s) | Available | 5 Day(s) | 16 | 28 | 37 | |

MYR 135.70 | 2 Piece(s) | Available | 10 Day(s) | 16 | 28 | 67 | |

MYR 66.30 | 1 Piece(s) | Available | 1 Day(s) | 20 | 32 | 42 | |

MYR 180.20 | 1 Piece(s) | Available | 5 Day(s) | 20 | 32 | 77 | |

MYR 118.62 | 2 Piece(s) | Available | 10 Day(s) | 25 | 40 | 58 | |

MYR 267.76 | 2 Piece(s) | Available | 10 Day(s) | 25 | 40 | 108 | |

MYR 122.46 | 1 Piece(s) | Available | 5 Day(s) | 30 | 45 | 68 | |

MYR 348.04 | 2 Piece(s) | Available | 10 Day(s) | 30 | 45 | 128 | |

MYR 257.48 | 2 Piece(s) | Available | 10 Day(s) | 40 | 60 | 80 | |

MYR 497.06 | 2 Piece(s) | Available | 10 Day(s) | 40 | 60 | 150 | |

MYR 362.60 | 2 Piece(s) | Available | 10 Day(s) | 50 | 80 | 90 | |

MYR 704.64 | 2 Piece(s) | Available | 10 Day(s) | 50 | 80 | 170 |

Loading...

| Part Number | d | D | L | L1 | H | T | d1 | d2 | t | P.C.D | W | F | A | |||||

| Type | Tolerance | Tolerance | Short | Long | ||||||||||||||

| Round Flanged C-MFM | Square Flanged C-MFK | Flanged type C-MFN | 10 | +0.028 0 | 19 | 0 -0.018 | 32 | 57 | 5 | 40 | 6 | 4.5 | 7.5 | 4.1 | 29 | 30 | - | 29 |

| 12 | +0.034 0 | 21 | 0 -0.021 | 32 | 57 | 10 | 42 | 32 | 32 | - | 32 | |||||||

| 16 | 28 | 37 | 67 | 48 | 38 | 37 | 22 | 31 | ||||||||||

| 20 | +0.041 0 | 32 | 0 -0.025 | 42 | 77 | 54 | 8 | 5.5 | 9 | 5.1 | 43 | 42 | 24 | 36 | ||||

| 25 | 40 | 58 | 108 | 62 | 51 | 50 | 32 | 40 | ||||||||||

| 30 | 45 | 68 | 128 | 74 | 10 | 6.6 | 11 | 6.1 | 60 | 58 | 35 | 49 | ||||||

| 40 | +0.050 0 | 60 | 0 -0.030 | 80 | 150 | 15 | 96 | 13 | 9 | 14 | 8.1 | 78 | 75 | 50 | 60 | |||

| 50 | 80 | 90 | 170 | 116 | 98 | 92 | 58 | 80 | ||||||||||

Basic Information

| Type | Housing Unit | Metal Type | Special Bronze Cast | Environment | Standard / In Oil |

|---|---|---|---|---|---|

| Housing Unit Type | Round Flange | Mounting Shaft Fits | g6 / f8 | Lubrication | Unlubricated / Regular Lubrication |

| Max. Allowable Surface Pressure P(N/mm2) | 29 | Case Material | Aluminum Alloy | Maximum Allowable Velocity(m/s) | 0.5 |

| Max. Allowable PV Value Range(N/mm2•m/s) | 1.1~2.0 | Max. Allowable PV Value(N/mm2•m/s) | 1.65 | Operating Temperature Range(°C) | -40::200 |

| Seal Type | No Seal |

Specification/Dimensions

-

Inner Dia. d(Ø)

-

Outer Dia. D(Ø)

-

Overall Length L(mm)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 1 Day(s) or Less

- 5 Day(s) or Less

- 10 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What is an oilless bushing and what features does it have?

-

Answer:

The bushing body is soaked in lubricating oil. It is a slide bearing which can be “used without oil supply” or “can reduce oil supply times”.

Oilless bushings have the following features:

1. Low maintenance frequency;

2. Compared with ball linear bearings, oilless bushings are suitable for low-speed and heavy-load occasions;

3. Allow use under severe conditions of high temperature and low temperature;

4. Compared with linear bearings, oilless bushings are thinner, saving space;

5. Allow use for both linear motion and rotary motion. - Question: What materials are MISUMI oilless bushings made of, and what features do they have respectively?

-

Answer:

MISUMI provides oilless bushings made of five materials, including copper alloy, bronze casting, dry type, resin and casting.

Copper alloys (metals) have high temperature resistance, excellent chemical resistance and impact resistance, and is suitable for heavy load and low-speed operation.

Bronze castings (metals) have excellent sintering resistance, can realize micro-operation, and are suitable for low-load and high-speed operation.

Dry (composite layers), resistant to high temperature, suitable for heavy load and low-speed operation, thin wall and compact.

Resin (resins), resistant to high temperature and chemicals (polytetrafluoroethylene resin), compliant with food hygiene law and suitable for low load and low-speed operation.

Castings (metals) are suitable for medium load and low-speed operation.

Additional Products in this Category

- Oil Free Bushing Housing Units - Standard Flanged - Standard - Built-In Copper Alloy Bushings, Single / Double

- Lubrication-Free Bushing Block Type Housing Unit, Tall / Standard Type, Built-in Dry Bushing Type

- Oil Free Bushings - High Precision

- Flange Integrated Oil Free Bushings - Copper Alloy, Pilot Flanged

- #500SP1-SL1, Bushing (SPB)

- #500HP SL1 Bushing (HPB)

- DAIBEST Bushing DBX Series

- Copper Alloy Shoulder Type Lubrication-Free Bushing

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy