(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 9:00 24/11/2024 to 7:00 (MYT) 25/11/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- Please note that E-Invoice will be sent to our customers by email. For more information, please read News.

High Temperature Insulating Grade,Heat Resistance Within 300 °C

High Temperature Insulating Grade,Heat Resistance Within 300 °C

Heat Insulating Plates are an economy item, The price is cheaper than the MISUMI standard product.They offer a wide variety of sizes to choose from.

[Feature]

● Plate Thickness Minimum/Maximum (mm.): 3 and 30

● Width and Length (mm.) : Can configurable between 20 to 800 mm, and the minimum length can be increased by increments 1 mm.

● Operating Environment Temperature (℃) : Normal temperature~300

● Main Material : Phenolic Modified Resin

[Application]

It is used for thermal insulation of connecting parts and thermal insulation of flanges

Part Number

Configured Part Number is shown.

Economy High Temp Insulating Plates

- Withstands high temperatures

- Made from phenolic modified resin and glass fiber

- Customizable sizes within specified range

- High compressive and bending strength for demanding applications

- Ideal for thermal insulation of connecting parts and flanges

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Product of Heat Insulating Plates Overview

It plays a great role in preventing heat diffusion, improving energy efficiency, distributing heat evenly, protecting peripheral components such as bearings and sensors, inhibiting heat deformation, etc.

Product of Heat Insulating Plates Features

Feature 2: The high-strength grade Heat Insulating Plates has high compressive strength and bending strength, so it is ideal for applications that require high strength.

Feature 3: The high temperature-resistant Heat Insulating Plates has small high-temperature expansion. It has compressive strength that hardly deteriorates at high temperature, exhibits less deformation under pressure, and maintains dimensional stability for a long time at high temperature.

Feature 4: The standard type and hole machining type of Heat Insulating Plates are available to satisfy your needs.

Feature 5: The Heat Insulating Plates products are provided in a rich variety to meet different requirements on high temperature and thermal conductivity.

Feature 6: Due to excellent Heat Insulating Plates effect, each product is dimensionally stable without deformation when heated within the operating temperature range.

Dimensional Drawing of Heat Insulating Plates

A≥B

A≥BSpecifications of Heat Insulating Plates Overview

| Type | Dimension tolerance of A·B | Main Substrate | Main Material | Grade | Color | Recommended Operating Environment Temperature |

| High Temperature Insulating Normal Insulating Grade | Unspecified P | Glass Fiber | Phenolic Modified Resin | General-Purpose Model | Brown | Normal temperature~300℃ |

For more information on product features, please see

For more information on product features, please see  Features of Heat Insulating Plates.

Features of Heat Insulating Plates.Example of Heat Insulating Plates Use

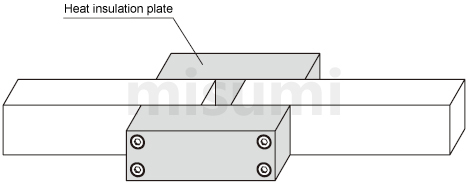

| Example of Heat Insulating Plates Use ① | Role of Heat Insulating Plates Product |

| Used for thermal insulation of connecting parts |

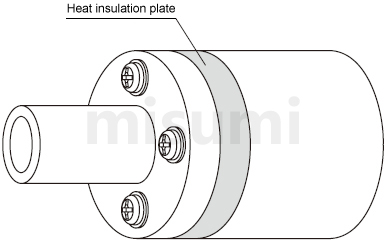

| Example of Heat Insulating Plates Use ② | Role of Heat Insulating Plates Product |

| Used for thermal insulation of flanges |

Precautions for Using Heat Insulating Plates

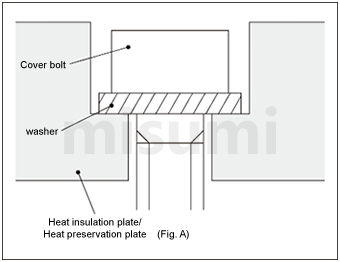

・Make sure to use bolts with washers, otherwise it may cause breakage due to excessive tightening. (Figure A)

・Do not use it in the environment containing moisture and drugs. Heat insulating plates containing moisture may crack or deteriorate significantly in performance with increasing temperature.

・ Because it is a laminating molded product, do not apply any force in the lamination direction (splitting direction) during use.

・ When used at a certain heating temperature, it may produce slight smell, which is not harmful, but please take ventilation measures and dispose of the smell as general smoke, keeping your face at a safe distance.

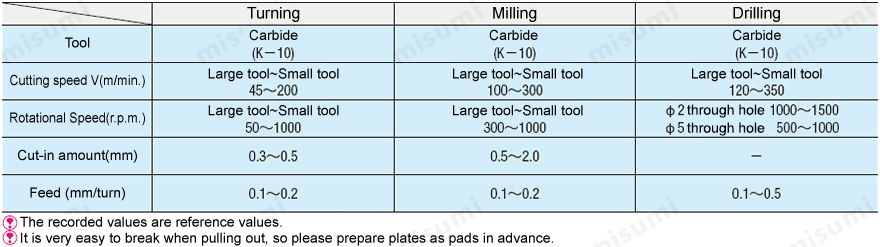

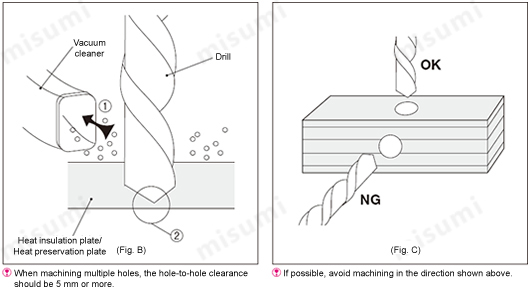

② Precautions for machining Heat Insulating Plates:

・During machining, please collect dust with a vacuum cleaner to avoid dust scattering. (Figure B)

Although it does not contain specific chemicals, such as asbestos, conventional dust operation safety measures such as wearing masks and protective glasses must be taken.

In addition, because it contains glass fibers, it may cause skin itching. It is recommended to wear gloves during operation. If sliding parts of other processing machines are covered with dust, the mechanical accuracy may deteriorate due to wear and tear.

・ When drilling and other hole opening operations are carried out, it may break, so you have to pay attention to the hole spacing, hole diameter and processing conditions.

・ The laminating molded product is not suitable for thread machining, three-dimensional machining, etc. Such machining operations as drilling and cutting in the lamination direction are main causes of cracking, so please avoid such operations whenever possible. (Figure C)

■ Recommended Heat Insulating Plates machining conditions

Related Industries of Heat Insulating Plates

Related Documents of Heat Insulating Plates

Here

Here Precautions for use of heat insulating plate Click

Here

HereRelated Products of Heat Insulating Plates

| Resin Washer Standard Type Single Product/Sold in Bags | Stopper bolt with urethane Straight type | Resin Collar Standard | ||

|  |  | ||

| Typical model: PACK-WSJJ4-2-2 | Typical model: UST8-40 | Typical model: CLJJ10-16-20.0 | ||

| Advantages: Single and packed products are available, with packed ones sold at more favorable prices. | Suitable for conveying heavy load workpieces, compact tip, usable in narrow spaces | Advantages: Optional inner and outer diameter and height, better price |

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

| Part Number |

|---|

| E-HIPHA2H-[20-800/1]-[5,15]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[5-795/0.5]-N[3,4,5,6,8,10] |

| E-HIPHA2H-[20-800/1]-[5,15]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[5-795/0.5]-Z[4,5,6,8] |

| E-HIPHA2H-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[5-795/0.5]-N[3,4,5,6,8,10] |

| E-HIPHA2H-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[5-795/0.5]-Z[4,5,6,8] |

| E-HIPHA4H-[20-800/1]-[5,15]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[9-791/0.5]-N[3,4,5,6,8,10] |

| E-HIPHA4H-[20-800/1]-[5,15]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[9-791/0.5]-Z[4,5,6,8] |

| E-HIPHA4H-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[9-791/0.5]-N[3,4,5,6,8,10] |

| E-HIPHA4H-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30]-F[9-791/0.5]-G[9-791/0.5]-Z[4,5,6,8] |

| E-HIPHA-[20-800/1]-[20-800/1]-[3,5,10,15,20,25,30] |

| E-HIPHAP2H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP2H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPHAP2H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-G[5-195/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP2H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-G[5-195/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPHAP2H-[20-200/1]-[5,10]-F[9-191/0.5]-F[9-191/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP2H-[20-200/1]-[5,10]-F[9-191/0.5]-F[9-191/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPHAP2H-[20-200/1]-[5,10]-F[9-191/0.5]-G[5-195/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP2H-[20-200/1]-[5,10]-F[9-191/0.5]-G[5-195/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPHAP2H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP2H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPHAP2H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-G[5-195/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP2H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-G[5-195/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPHAP2H-[20-200/1]-[20-200/1]-F[9-191/0.5]-F[9-191/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP2H-[20-200/1]-[20-200/1]-F[9-191/0.5]-F[9-191/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPHAP2H-[20-200/1]-[20-200/1]-F[9-191/0.5]-G[5-195/0.5]-G[5-195/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP2H-[20-200/1]-[20-200/1]-F[9-191/0.5]-G[5-195/0.5]-G[5-195/0.5]-Z[4,5,6,8] |

| E-HIPHAP4H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP4H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPHAP4H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-G[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP4H-[20-200/1]-[5,10]-[3,5,10,15,20,25,30]-G[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPHAP4H-[20-200/1]-[5,10]-F[9-191/0.5]-F[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP4H-[20-200/1]-[5,10]-F[9-191/0.5]-F[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPHAP4H-[20-200/1]-[5,10]-F[9-191/0.5]-G[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP4H-[20-200/1]-[5,10]-F[9-191/0.5]-G[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPHAP4H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP4H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-F[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPHAP4H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-G[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP4H-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30]-G[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPHAP4H-[20-200/1]-[20-200/1]-F[9-191/0.5]-F[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP4H-[20-200/1]-[20-200/1]-F[9-191/0.5]-F[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPHAP4H-[20-200/1]-[20-200/1]-F[9-191/0.5]-G[9-191/0.5]-G[9-191/0.5]-N[3,4,5,6,8,10] |

| E-HIPHAP4H-[20-200/1]-[20-200/1]-F[9-191/0.5]-G[9-191/0.5]-G[9-191/0.5]-Z[4,5,6,8] |

| E-HIPHAP-[20-200/1]-[20-200/1]-[3,5,10,15,20,25,30] |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Plate Thickness T (mm) | Width B (mm) | Length A (mm) | Tolerance Selection | Type | Number of Holes | Counterbored Hole (Screw Dia.) [Z] | Through Hole (Screw Dia.) [N] | F (mm) | G (mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 800 | Not specified | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 791 | 5 ~ 795 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 800 | Not specified | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 791 | 5 ~ 795 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 791 | 5 ~ 795 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 791 | 5 ~ 795 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 800 | Not specified | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 791 | 9 ~ 791 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 800 | Not specified | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 791 | 9 ~ 791 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 791 | 9 ~ 791 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 791 | 9 ~ 791 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 800 | 20 ~ 800 | Not specified | Standard type | - | - | - | - | - | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | - | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | - | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | - | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | - | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | - | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | - | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | - | - | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | - | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | - | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | - | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | 9 ~ 191 | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | - | 3 ~ 10 | - | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 2H (2 holes) | 4 ~ 8 | - | - | 5 ~ 195 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | - | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | - | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | - | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | - | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | - | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | - | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | - | - | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | - | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | - | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | - | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | 9 ~ 191 | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | - | 3 ~ 10 | - | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | - | 20 ~ 200 | 20 ~ 200 | P | Hole machining type | 4H (4 holes) | 4 ~ 8 | - | - | 9 ~ 191 | ||

- | 1 Piece(s) | 13 Day(s) | 3 ~ 30 | 20 ~ 200 | 20 ~ 200 | P | Standard type | - | - | - | - | - |

Loading...

A≥B

A≥B| Type | Dimension tolerance of A·B | Main Substrate | Main Material | Grade | Color | Recommended Operating Environment Temperature |

| High Temperature Insulating Normal Insulating Grade | Unspecified P | Glass Fiber | Phenolic Modified Resin | General-Purpose Model | Brown | Normal temperature~300℃ |

Dimension Specification Table

■Standard Type

| Part Number | 1mm increments | Selection T T | ||

Type Type | Tolerance Selection |  A A |  B B | |

| A≥B | ||||

| High Temperature Insulating Normal Insulating Grade | Unspecified (+1.0, 0) P (±0.3) | 20 to 800 | 20 to 800 | 3 5 10 15 20 25 30 |

| 20~200 | 20 to 200 | |||

■Hole machining type

| Part Number | 1mm increments | Selection T T | 0.5mm increments |  Bolt Nominal Diameter Selection Bolt Nominal Diameter Selection | |||||

Type Type | Tolerance Selection |  Number of Holes Number of Holes |  A A |  B B |  F F |  G G | N | Z | |

| A≥B | |||||||||

| High Temperature Insulating Normal Insulating Grade | Unspecified (+1.0, 0) | 2H 4H | 20~800 | 20 to 800 | 3 | 9~791 | 5 to 795 (2H) 9 to 791 (4H) | 3 4 5 6 8 10 | - |

| 5 | - | ||||||||

| 10 | 4 5 6 | ||||||||

| 15 | 4 5 6 8 | ||||||||

| 20 | 4 5 6 8 | ||||||||

| 25 | 4 5 6 8 | ||||||||

| 30 | 4 5 6 8 | ||||||||

| P (±0.3) | 20~200 | 20 to 200 | 3 | 9~191 | 5 to 195 (2H) 9 to 191 (4H) | - | |||

| 5 | - | ||||||||

| 10 | 4 5 6 | ||||||||

| 15 | 4 5 6 8 | ||||||||

| 20 | 4 5 6 8 | ||||||||

| 25 | 4 5 6 8 | ||||||||

| 30 | 4 5 6 8 | ||||||||

The specified range of Dimension F must satisfy: d(d1)+5≤F≤A-d(d1)-5.

The specified range of Dimension F must satisfy: d(d1)+5≤F≤A-d(d1)-5. When selecting the 2H type, the specified range of Dimension G must satisfy: d(d1)/2+2.5≤G≤B-d(d1)/2-2.5. When selecting the 4H type, it must satisfy: d(d1)+5≤G≤B-d(d1)-5. (When selecting d for through hole and d1 for counterbored hole)

When selecting the 2H type, the specified range of Dimension G must satisfy: d(d1)/2+2.5≤G≤B-d(d1)/2-2.5. When selecting the 4H type, it must satisfy: d(d1)+5≤G≤B-d(d1)-5. (When selecting d for through hole and d1 for counterbored hole) When selecting the machining type with hole, please select N (through hole) and Z (counterbored hole).

When selecting the machining type with hole, please select N (through hole) and Z (counterbored hole).| Hole Machining Detail | |||||||||||||||||||||||||||||||||

| N (Through hole) | Z (Counterbored Hole) | ||||||||||||||||||||||||||||||||

|  | ||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||

Basic Information

| Recommended Operating Temperature(°C) | Room Temp. ~ 300 | Grade | High Temperature Insulating Normal Insulating Grade | Color | Brown |

|---|---|---|---|---|---|

| Thermal Conductivity(W/m·K) | 0.24 | Expansion Rate(℃-1) | 0.000076 | Main Base Material | Glass Fiber |

| Main Material | Phenolic Modified Resin |

Specification/Dimensions

-

Plate Thickness T(mm)

-

Width B(mm)

-

Length A(mm)

-

Tolerance Selection

- Not specified

- P

-

Type

- Hole machining type

- Standard type

-

Number of Holes

- 2H (2 holes)

- 4H (4 holes)

-

Counterbored Hole (Screw Dia.) [Z]

-

Through Hole (Screw Dia.) [N]

-

F(mm)

-

G(mm)

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 13 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: What is the reason for the poor heat insulation effect of the purchased heat insulation plate?

- Answer: The heat insulation effect of the heat insulation plate is related to the thermal conductivity and the plate thickness. The lower the thermal conductivity, the greater the thickness, the better the heat insulation effect. It is also related to the working condition (if applicable) of the heat insulation plate used.

- Question: Is the operating temperature of the heat insulation plate the guaranteed value?

- Answer: The operating temperature of the heat insulation plate is the recommended operating temperature, which refers to the temperature where the quality will not drop sharply after a certain period of long-term use.

- Question: Is it possible to purchase MISUMI heat insulation plate and then make alterations by oneself?

- Answer: Yes. However, be sure to refer to the processing precautions and heat insulation plate processing conditions in the precautions. In addition, it is recommended that the hole should be at least 5mm thick from the edge of the material.

- Question: Is there a big difference between the materials of economy series heat insulation plate and imported heat insulation plate?

- Answer: The economy series heat insulation plate is made of domestically produced materials with fully evaluated performance and close to the quality of imported heat insulation plate, but more cost-effective.

Additional Products in this Category

- Heat Insulating Plates/High Strength/High Temperature Resistant Grade

- High Temperature Insulation Sheets

- Machined Resin Plates

- Heat Insulating Plates (High Temperature Insulating Grade)

- Heat Insulating Plates Normal Grade, Temperature Resistance Within 220 °C

- High Strength, Normal Grade, Heat Resistance Within 220 °C

- High Strength and High Temperature Insulating Grade, Heat Resistance Within 300 °C

- Silicone Sponge Square Tube

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy