(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Scheduled Maintenance Notice: This site will be unavailable due to scheduled maintenance from 9:00 24/11/2024 to 7:00 (MYT) 25/11/2024. We apologize for the inconvenience.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More information.

- Please note that E-Invoice will be sent to our customers by email. For more information, please read News.

Cartridge Heaters With Sensor

- Volume Discount

Cartridge Heaters With Sensor

These cartridge heaters are used in various industrial applications to provide localized heat to the equipment. They provide a wide range of sizes to choose from

[Feature]

- Maximum Operating Temperature (°C) : 600

- Diameter (mm.) : 8, 10 and 12

- Length (mm.) : 50, 80, 120 and 150

- Voltage(V) : 220

- Material:

Heater - SUS321

[Application]

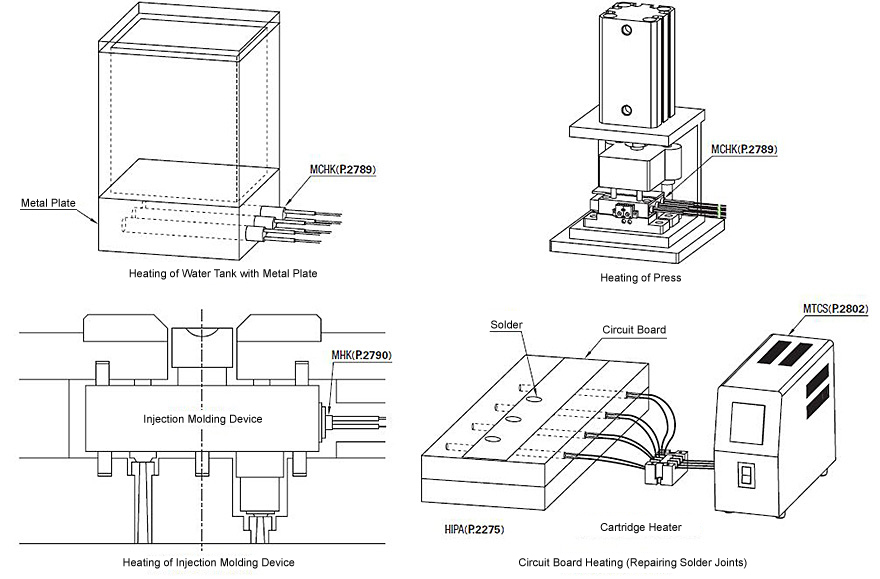

These cartridge heaters are often used in industrial processes such as plastic molding, packaging and sealing.

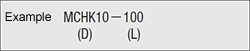

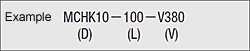

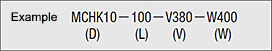

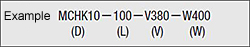

Part Number

Configured Part Number is shown.

Economy Cartridge Heater with Sensor

- Maximum Operating Temperature: Handle demanding tasks in harsh environments with confidence.

- The integrated sensor ensures accurate temperature readings, allowing for tight process control and consistent results.

- Choose from a range of diameters and lengths to match your specific application needs.

- Cartridge heater with multiple wattage options

- Durable SUS321 Stainless Steel Construction: Built to last, these heaters resist corrosion and provide long service life.

![]()

MISUMI Standard

![]()

Cheaper Price

![]()

Product Variety

![]()

3D CAD Support

Cartridge Heaters Product Overview

The Cartridge Heaters is a durable and highly versatile product. It is widely used in heavy-industry applications such as plastics and packaging, emergency care medical equipment and analytical test instruments in aircrafts, train compartments and trucks, etc.

It can serve as a thermally conductive source for heating solid metal plates, modules and molds, and a convective heat source for various liquids and gases.

Cartridge Heaters Product Feature

■ Difference between MISUMI Economy series and generic Cartridge Heaters products in the market

| Cartridge Heaters Products circulating on the market * | MISUMI economy series | |

| Service life test equivalent to 4,000 H* |  |  |

| Result | Cannot be used due to short circuit or breakage | Can be used normally |

* Generic Cartridge Heaters products in the market are similar products randomly purchased by our company from online or offline markets

* The test data are obtained through testing by our company, which are for reference only

Cartridge Heaters Dimensional Drawing

D Tolerance * The tolerance is the value of the heating part

| D(mm) | Tolerance (mm) |

| 5~12 | -0.03 -0.06 |

Cartridge Heaters Maximum operating temperature: 600℃

Cartridge Heaters Maximum operating temperature: 600℃ Lead wire heat-resistant temperature: 260℃

Lead wire heat-resistant temperature: 260℃・Material table

Material

MaterialBody: SUS321

Lead wire: Nickel (Ni)

Lead wire coating: PTFE

Cartridge Heaters Example of Use

|  |  |

| Move parts related to mechanism sliding support, temperature adjusting and heating with racks, gears and other workpieces. | Check 3 types of parts related to the sliding support, temperature adjusting and heating in the same position. | Belt tension device (with the spring) |

|  |  |

| Cartridge Heaters Parts related to the sliding support, nut, profile, temperature adjusting and heating | Slide up and down through clamping & welding parts of the cam bearing mechanism | No need to worry about handling of inductor wiring even for reversely rotating objects |

For more examples of product use, please refer to

//th.misumi-ec.com/en/asia/incadlibrary/keyword.html?keyword=%E7%AD%92%E5%BC%8F%E5%8A%A0%E7%83%AD%E5%99%A8¤tPage=1.

Cartridge Heaters Precautions

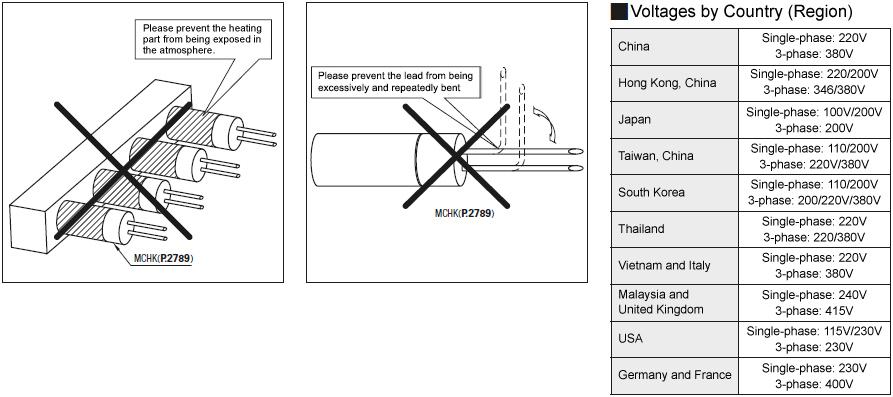

① Do not let the heater dry burn in the atmosphere. Otherwise, even if only heating part of the heater is exposed outside the object heated, the wire may break and cause a fire due to abnormal heating.

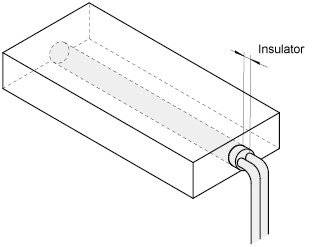

② Do not let the lead wire and insulator of the heater come into contact with water. Otherwise, it may cause electric leakage or short circuit.

③ The oil and grease used for processing holes in the heated part should be removed. Otherwise, abnormal heat may be generated due to carbonization.

④ An abnormally short ON-OFF cycle may have an adverse effect on the service life of the heater. It is recommended to use a controller controlled by PID.

⑤ The nickel pin at the root of the lead wire may be broken after being bent repeatedly.

⑥ Do not use a power supply with the voltage exceeding the rated voltage (V).

⑦ When removing the heater from the object heated, make sure to turn off the power first. Do not touch the heater immediately after turning off the power.

⑧ The temperature around the lead wire outlet shall be kept below 130℃.

⑨ When the flanged heater is used, the temperature around the flange shall be kept below 180°C.

⑩ Do not use it in the vacuum.

⑪ When heating, the heater will expand and may cause the heat-generating part to protrude from the mounting hole. It is recommended to fix the heater with screws.

⑫ Choose a voltage that is suitable for the operating environment. If you use a voltage that exceeds the rated value, the heater may be damaged.

* Other precautions for each type of cartridge heaters are recorded on each product page. Please make sure to follow the above precautions and operate the heater properly.

Cartridge Heaters Specifications Overview

① Determine the required heater heat (W).

It can be calculated with the following formula according to the mass, specific heat, rising temperature, and the heating time required to reach the set temperature of the object heated.

Cartridge Heaters The efficiency varies with the heat preservation, thermal insulation, and settings of the heater, so it is difficult to calculate it correctly. Generally, the value of about 0.2 to 0.5 is preferred.

② Determine the number of heaters and the heat of each heater (W).

The number of heaters is subject to the size of the object heated, and the total heat (W) is the heat required by the object heated.

Example) Use 2 heaters of 550 (W) (1,100 W in total).

● Selection of the cartridge heater (P.2789 MCHK type)

| ① Determine the diameter and length of the heater | ② Determine the voltage (V) to be used | ③ Determine the heat (W) required for the object heated |

|  |  |

Note: For the power (W) of the L Dimension ・W (Power) Fixed Type, please select a product with the power (W) larger than the required heat (W).

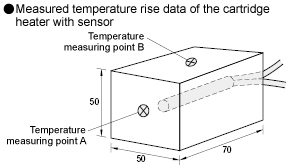

● Measurement data of the temperature rise time by power

Cartridge Heaters Related Products

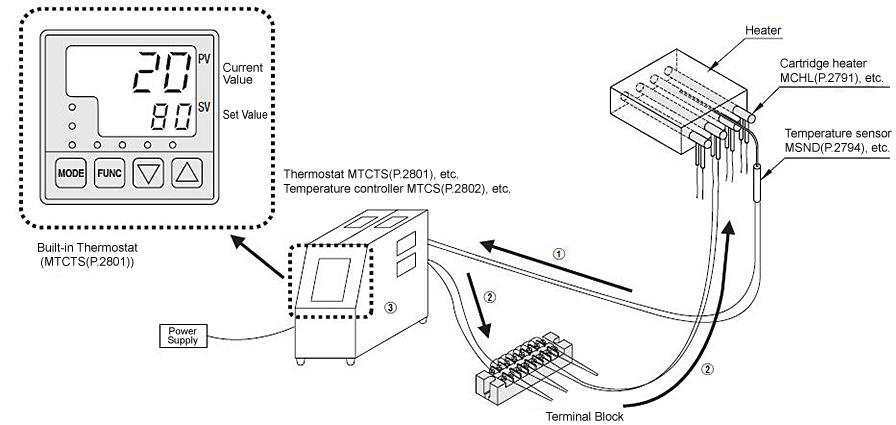

■Overview

・The common specifications of MISUMI heaters have been standardized, which can satisfy the users’ needs of shortening the delivery time.

・ The temperature sensor and temperature controller, etc. required to control the heater can also be selected from the catalog.

■Basic structure (example)

・As shown in the figure below, the heater shall be used in combination with the temperature sensor and temperature controller.

・ Temperature adjusting procedure

■ Example of Cartridge Heaters use

① The temperature detected by the temperature sensor is regarded as the current value (PV) of the temperature controller.

② As shown in the above basic structure (an example), when the set temperature (SV) of the temperature controller is 80°C and the current value (PV) is 20°C, the temperature controller will apply a voltage (ON) to enable heating-up of the heater.

③ If the voltage (ON) is maintained all the time, the temperature will exceed the set value (SV) of 80°C. Therefore, when the temperature rises to around the set value (SV) 80°C, the temperature controller will stop applying the voltage (OFF).

When the current value of the temperature (PV) is

Cartridge Heaters Usage Method

● Please minimize the mounting hole gap of the heated metal block as much as possible.

When the metal block mounting hole is machined, it is recommended to keep the gap below 0.05 on one side.

* The size of gap between the heater and object heated will affect the service life of the heater. When a large gap will extend, a drilling hole can be used, but it is recommended that all heaters use reamed mounting holes. The temperature rise time may cause the response speed of the temperature controller to slow down. The temperature of the object heated is controlled below 300°C.

* The service life of the heater may change greatly due to the environment. The improper operating temperature and temperature adjusting method may cause wire breakage in a short period of time. Therefore, it is recommended to prepare the backup cartridge heater.

Part Number

CAD Data download and 3D preview are not available because the part number has not yet been determined.

- *In order to open the CAD Data download and 3D preview screen, the part number must be fixed.

- Please confirm the part number from "Specification / Dimension"on the left side, and then perform the CAD Data Download / 3D Preview operation.

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Diameter (Ø) | Length (mm) | Rated Flow (W) |

|---|---|---|---|---|---|---|---|

MYR 104.76 | 1 Piece(s) | Available | 9 Day(s) | 8 | 50 | 80 | |

MYR 104.76 | 1 Piece(s) | Available | 5 Day(s) | 8 | 50 | 100 | |

MYR 124.48 | 1 Piece(s) | Available | 1 Day(s) | 8 | 80 | 120 | |

MYR 124.48 | 1 Piece(s) | Available | 9 Day(s) | 8 | 80 | 160 | |

MYR 137.02 | 1 Piece(s) | Available | 1 Day(s) | 8 | 120 | 200 | |

MYR 137.02 | 1 Piece(s) | Available | 9 Day(s) | 8 | 120 | 280 | |

MYR 144.18 | 1 Piece(s) | Available | 9 Day(s) | 8 | 150 | 260 | |

MYR 144.18 | 1 Piece(s) | Available | 9 Day(s) | 8 | 150 | 350 | |

MYR 104.76 | 1 Piece(s) | Available | 9 Day(s) | 10 | 50 | 90 | |

MYR 104.76 | 1 Piece(s) | Available | 9 Day(s) | 10 | 50 | 120 | |

MYR 124.48 | 1 Piece(s) | Available | 9 Day(s) | 10 | 80 | 150 | |

MYR 124.48 | 1 Piece(s) | Available | 1 Day(s) | 10 | 80 | 200 | |

MYR 137.02 | 1 Piece(s) | Available | 9 Day(s) | 10 | 120 | 250 | |

MYR 137.02 | 1 Piece(s) | Available | 9 Day(s) | 10 | 120 | 350 | |

MYR 144.18 | 1 Piece(s) | Available | 9 Day(s) | 10 | 150 | 320 | |

MYR 144.18 | 1 Piece(s) | Available | 9 Day(s) | 10 | 150 | 450 | |

MYR 110.12 | 1 Piece(s) | Available | 9 Day(s) | 12 | 50 | 90 | |

MYR 110.12 | 1 Piece(s) | Available | 9 Day(s) | 12 | 50 | 150 | |

MYR 124.48 | 1 Piece(s) | Available | 9 Day(s) | 12 | 80 | 140 | |

MYR 124.48 | 1 Piece(s) | Available | 9 Day(s) | 12 | 80 | 180 | |

MYR 124.48 | 1 Piece(s) | Available | 9 Day(s) | 12 | 80 | 230 | |

MYR 153.16 | 1 Piece(s) | Available | 9 Day(s) | 12 | 120 | 250 | |

MYR 153.16 | 1 Piece(s) | Available | 9 Day(s) | 12 | 120 | 380 | |

MYR 160.32 | 1 Piece(s) | Available | 9 Day(s) | 12 | 150 | 300 | |

MYR 160.32 | 1 Piece(s) | Available | 9 Day(s) | 12 | 150 | 500 |

Loading...

| Part Number | Diameter (D) mm | Length (L) mm | Rated Capacity W | Rated Voltage V | Power Density W/cm² |

| With Sensor | 8 | 50 | 80 | 220 | 6.3 |

| 50 | 100 | 220 | 8 | ||

| 80 | 120 | 220 | 6 | ||

| 80 | 160 | 220 | 8 | ||

| 120 | 200 | 220 | 6.6 | ||

| 120 | 280 | 220 | 9.3 | ||

| 150 | 260 | 220 | 6.9 | ||

| 150 | 350 | 220 | 9.3 | ||

| 10 | 50 | 90 | 220 | 5.7 | |

| 50 | 120 | 220 | 7.6 | ||

| 80 | 150 | 220 | 6 | ||

| 80 | 200 | 220 | 8 | ||

| 120 | 250 | 220 | 6.6 | ||

| 120 | 350 | 220 | 9.3 | ||

| 150 | 320 | 220 | 6.8 | ||

| 150 | 450 | 220 | 9.6 | ||

| 12 | 50 | 90 | 220 | 4.8 | |

| 50 | 150 | 220 | 8 | ||

| 80 | 140 | 220 | 4.6 | ||

| 80 | 180 | 220 | 6 | ||

| 80 | 230 | 220 | 7.6 | ||

| 120 | 250 | 220 | 5.5 | ||

| 120 | 380 | 220 | 8.4 | ||

| 150 | 300 | 220 | 5.3 | ||

| 150 | 500 | 220 | 8.8 |

Basic Information

| Maximum Operating Temperature(°C) | 600 | Rated Voltage(V) | 220 |

|---|

Specification/Dimensions

-

Diameter(Ø)

-

Length(mm)

-

Rated Flow(W)

-

type

- E-MCHSSS

-

CAD

- 2D

- 3D

Days to Ship

-

- All

- 1 Day(s) or Less

- 5 Day(s) or Less

- 9 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently asked question (FAQ)

- Question: Is there a criterion for judging the selection of the controller for the cartridge heater?

- Answer: There is a detailed controller selection criterion in the cartridge heater product introduction for reference. Customers can choose the configuration by themselves.

- Question: Are there any examples or tips on the installation of cartridge heaters? Improper handling can easily cause damage.

- Answer: There are detailed information on product installation and precautions in this product introduction. Please read it carefully before installing.

- Question: Can the heating rod product be used in air or water?

- Answer: MISUMI's cartridge heater product cannot be used in air or water. It will cause the body temperature to be too high, which will damage the heater body, and may even cause a fire in the open flame.

Additional Products in this Category

- Cartridge Heaters Items - Anti-Seize Agent

- Cartridge Heaters-Selectable/Configurable L&W

- Cartridge Heaters-No Protective Spring/With Protective Spring/Flange Shape A/Flange Shape B/Flange Shape C

- Cartridge Heaters-L-Shaped/Break Resistant, Internal Connection)

- Cartridge Heaters-High Temperature/No Flange/Flange Shape A/Flange Shape B

- Cartridge Heaters Internal Wiring Type

- Cartridge Heaters Standard Type

- Firerod Cartridge Heater

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy