(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

50,000 Stock items for Same Day Ship Out.

All Categories

Categories

- Automation Components

A wide variety of standard and configurable components for factory automation engineers in industries such as automotive, semiconductor, packaging, medical and many more.

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Discharging / Painting Devices

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Framing & Support

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjusting, Fastening, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

A good selection of accessories such as screws, bolts, washers and nuts that you may need for your daily engineering usage.

- Materials

Browse industrial materials ranging from heat insulating plates, sponges, to metal and plastic materials in different sizes to meet your various applications.

- Wiring Components

A wide variety of wiring parts for connecting and protecting control and PC parts including Connectors, Cables, Electric Wires, Crimping Terminals and more.

- LAN Cables / Industrial Network Cables

- Cables by Application

- Cables with Connectors

- RS232 / Personal Computers / AV Cables

- Wires/Cables

- Connectors (General Purpose)

- Crimp Terminals

- Zip Ties

- Cable Glands

- Cable Bushings/Clips/Stickers

- Screws/Spacers

- Cable Accessories

- Tubes

- Protection Tubes

- Ducts/Wiremolds

- General Purpose Tools

- Dedicated Tools

- Soldering Supplies

- Electrical & Controls

A wide variety of controls and PC parts for electrical engineers including Controls, Powers, PC parts and more.

- Cutting Tools

A wide variety of cutting tools for many uses and work materials including End Mills, Drills, Cutters, Reamers, Turning Tools and more.

- Carbide End Mills

- HSS End Mills

- Milling Cutter Inserts/Holders

- Customized Straight Blade End Mills

- Dedicated Cutters

- Turning Tools

- Drill Bits

- Screw-Hole-Related Tools

- Reamers

- Chamfering / Centering Tools

- Fixtures Related to Cutting Tools

- Step Drills

- Hole Saws

- Clean Key Cutters

- Core Drills (Tip Tools)

- Magnetic Drilling Machine Cutters

- Drill Bits for Electric Drilling Machines

- Woodworking Drill Cutters

- Drills for Concrete

- Processing Tools

A wide variety of tools and supplies used in processing including Machine Tools, Measurement Tools, Grinding and Polishing Supplies and more.

- Material Handling & Storage

A wide variety of goods used in shipment, material handling and warehouse including Tape supplies, Stretch film, Truck, Shelf, Crane and more.

- Tape Supplies

- Cushioning Materials

- Stretch Films

- Cardboard

- Plastic Bags

- PP Bands

- Magic Tapes / Tying Belts

- Rubber Bands

- Strings/Ropes

- Cable Ties

- Tags

- Labelers

- Unpacking Cutters

- Packing Support Equipment

- Cloth Sheets for Packing

- Conveyance/Dolly Carts

- Tool Wagons

- Tool Cabinets / Container Racks

- Lifters / Hand Pallets

- Container Pallets

- Storage Supplies

- Shelves/Racks

- Work Benches

- Suspended Clamps/Suspended Belts

- Jack Winches

- Chain Block Cranes

- Bottles/Containers

- Bicycle Storage Area

- Safety & General Supplies

A large variety of goods for every kind of factories and offices including Protection items, Cleaning supplies, sanitations, office supplies and more.

- Lab & Clean Room Supplies

A large variety of items used in R&D and Clean Room including research Equipment, Laboratory Essentials, Analysis Supplies, Clean Environment-Related Equipment and more.

- Press Die Components

Choose from thousands of standard stamping die components including Punch & Die, Gas Springs, Guide Components, Coil Springs and many more.

- Plastic Mold Components

Browse our wide variety of mold components including Ejector Pins, Sleeves, Leader Components, Sprue Bushings and many more.

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

Browse our injection molding components including Heating Items, Couplers, Hoses and more.

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Chemical for Injection Molding

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Search by Application

Brands

- Please note that some of the items may take longer lead time to ship due to Japan New Year holidays (29-Dec-2024 to 5-Jan-2025). Early order placement is recommended. We apologize for the inconvenience caused and appreciate your kind understanding. [Details]

- Please note that E-Invoice will be sent to our customers by email. For more information, please read News.

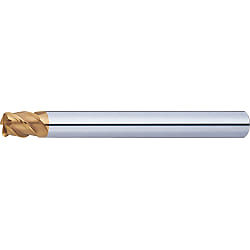

TSC series carbide radius end mill, high-feed, high-rigidity, 4-flute, 45° spiral / stub model

- Volume Discount

[Features]

·High rigid and cutting sharpness are achieved through combination of negative blade radius, appropriate core diameter, and 45° helix angle, enabling high-efficiency machining with high feed

·By adopting stub flute length that has same flute length as cutting diameter, it is possible to process bottom surface while suppressing chattering

·Versatile type that can be used for engraving, side surfaces, coarse, and middle finish

·Can be regrinded. Please refer to the page dedicated to "regrinding service" for usage procedures, range of services, prices, etc.

- TS

- High-Hardness Steel

- 4 Flutes

- B (Stub)

Part Number

Configured Part Number is shown.

| Part Number |

|---|

| TSC-CR-HFEM4B2-R0.5 |

| TSC-CR-HFEM4B3-R0.8 |

| TSC-CR-HFEM4B4-R1 |

| TSC-CR-HFEM4B5-R1.2 |

| TSC-CR-HFEM4B6-R1.5 |

| TSC-CR-HFEM4B8-R2 |

| TSC-CR-HFEM4B10-R2 |

| TSC-CR-HFEM4B12-R2 |

| Part Number | Standard Unit Price | Minimum order quantity | Volume Discount | Days to Ship | Outer Diameter (D) (φ) | R Size (mm) | Flute Length (ℓ) (mm) | Overall Length (L) (mm) | Shank Diameter (d) (mm) | Figure |

|---|---|---|---|---|---|---|---|---|---|---|

MYR 230.50 | 1 Piece(s) | Available | 4 Day(s) or more | 2 | 0.5 | 2 | 50 | 4 | 1 | |

MYR 248.38 | 1 Piece(s) | Available | 4 Day(s) or more | 3 | 0.8 | 3 | 50 | 4 | 1 | |

MYR 248.38 | 1 Piece(s) | Available | 4 Day(s) or more | 4 | 1 | 4 | 50 | 6 | 1 | |

MYR 273.47 | 1 Piece(s) | Available | 4 Day(s) or more | 5 | 1.2 | 5 | 70 | 6 | 1 | |

MYR 309.18 | 1 Piece(s) | Available | 4 Day(s) or more | 6 | 1.5 | 6 | 70 | 6 | 2 | |

MYR 404.80 | 1 Piece(s) | Available | 4 Day(s) or more | 8 | 2 | 8 | 80 | 8 | 2 | |

MYR 446.42 | 1 Piece(s) | Available | 4 Day(s) or more | 10 | 2 | 10 | 90 | 10 | 2 | |

MYR 610.99 | 1 Piece(s) | Available | 4 Day(s) or more | 12 | 2 | 12 | 100 | 12 | 2 |

Loading...

Specifications

| Model Number | Flute Length ℓ |

Overall Length L |

Shank Diameter d |

Figure | ||

| Outer Diameter D |

Radius R |

|||||

| TSC-CR-HFEM4B | 2 | 0.5 | 2 | 50 | 4 | 1 |

| 3 | 0.8 | 3 | 50 | 4 | 1 | |

| 4 | 1 | 4 | 50 | 6 | 1 | |

| 5 | 1.2 | 5 | 70 | 6 | 1 | |

| 6 | 1.5 | 6 | 70 | 6 | 2 | |

| 8 | 2 | 8 | 80 | 8 | 2 | |

| 10 | 2 | 10 | 90 | 10 | 2 | |

| 12 | 2 | 12 | 100 | 12 | 2 |

For Cutting Conditions, Refer to >>Click here.

More Information

● It has a TS film coating with much greater oxidation resistance and hardness than conventional films, resulting in a longer operational life and ideal for high speed machining / dry machining.

● The combination of a radius with negative flutes, appropriate core thickness and 45° twist yields an improved high-capacity machining thanks to the high rigidity, sharpness and high feed rate.

● Has a stubby blade with a flute length equal to the blade diameter, suppressing chatter while machining bottom surfaces.

● Universal model capable of everything from engraving through to side-surface, coarse and medium finishing.

Basic Information

| Work Material | General Steel / Heat-Treated Steel / High-Hardness Steel ~ HRC55 / High-Hardness Steel ~ HRC60 / High-Hardness Steel – HRC65 / Stainless Steel / Cast Iron | Number of Flutes(sheet) | 4 | Model | High-Feed Radius |

|---|---|---|---|---|---|

| Processing Applications | Flat Surface / Side Surface / Curved Surface / Inclined Cutting | Coating | For High Hardness (Silicone-Based) | Torsion Angle (θ) | Powerful Helix (45° to 60°) |

| R Precision(μm) | ±0.015 | Additional Classification | Stocked Product |

Specification/Dimensions

-

Outer Diameter (D)(φ)

-

R Size(mm)

-

Flute Length (ℓ)(mm)

-

Overall Length (L)(mm)

-

Shank Diameter (d)(mm)

-

type

- TSC-CR-HFEM4B

Days to Ship

-

- All

- 4 Day(s) or Less

Specify Alterations

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Additional Products in this Category

- TSC series carbide radius end mill, 3-flute, 45° spiral / stub model

- TSC Series Carbide Radius End Mill, 3-Flute / 45° Spiral / Short Type

- TSC series carbide radius end mill, 3-flute, 45° spiral, stub / tapered neck model

- VAC Series Carbide 2-Flute Radius End Mill

- GS MILL Hard Radius GSH-R

- X's Mill Geo Radius 4XSGEO-R

- Solid End Mill for Aluminum Machining AL-SEES3-LS-R Type

- End Mill with 2 Carbide Flutes and Corner Radius KSER-2

Customers Who Viewed This Item Also Viewed

-

TSC Series Carbide Uneven Lead 4-Flute Radius End Mill

TSC Series Carbide Uneven Lead 4-Flute Radius End MillMISUMI

Standard Price : MYR 161.85-

Days to Ship : 4 Day(s) or more

-

TSC series carbide radius end mill, high-feed, high-rigidity, 4-flute / no side blade

TSC series carbide radius end mill, high-feed, high-rigidity, 4-flute / no side bladeMISUMI

Standard Price : MYR 234.06-

Days to Ship : 4 Day(s) or more

-

TSC series carbide radius end mill, high-feed, high-rigidity, 4-flute, 45° spiral / short model

TSC series carbide radius end mill, high-feed, high-rigidity, 4-flute, 45° spiral / short modelMISUMI

Standard Price : MYR 314.36-

Days to Ship : 4 Day(s) or more

-

-

TSC series carbide radius end mill, 4-flute, 45° spiral / long shank, short model

TSC series carbide radius end mill, 4-flute, 45° spiral / long shank, short modelMISUMI

Standard Price : MYR 359.82-

Days to Ship : 4 Day(s) or more

-

TSC series carbide radius end mill, high-feed, high-rigidity, 3-flute, 45° spiral / stub model

TSC series carbide radius end mill, high-feed, high-rigidity, 3-flute, 45° spiral / stub modelMISUMI

Standard Price : MYR 315.37-

Days to Ship : 4 Day(s) or more

-

TSC series carbide composite radius end mill, for high-feed machining, 4-flute, 45° spiral / short model

TSC series carbide composite radius end mill, for high-feed machining, 4-flute, 45° spiral / short modelMISUMI

Standard Price : MYR 373.97-

Days to Ship : 4 Day(s) or more

-

TSC Series Carbide Radius End Mill for High-Hardness Copper Machining, Multi-Blade, Spiral / Stub Model

TSC Series Carbide Radius End Mill for High-Hardness Copper Machining, Multi-Blade, Spiral / Stub ModelMISUMI

Days to Ship : 4 Day(s) or more

-

TiAlN Coated Carbide Drill for Cast Iron Machining, 3-Flute / Regular

TiAlN Coated Carbide Drill for Cast Iron Machining, 3-Flute / RegularMISUMI

Standard Price : MYR 283.86-

Days to Ship : 4 Day(s) or more

-

-

TSC series carbide radius end mill, 4-flute, 45° spiral / short, long neck model

TSC series carbide radius end mill, 4-flute, 45° spiral / short, long neck modelMISUMI

Standard Price : MYR 335.87-

Days to Ship : 4 Day(s) or more

-

Carbide Radius End Mill for Aluminum Machining, 2-Flute / Regular Model

Carbide Radius End Mill for Aluminum Machining, 2-Flute / Regular ModelMISUMI

Days to Ship : 4 Day(s) or more

Tech Support

- Factory Automation, Electronics, Tools, & MRO (Maintenance, Repair and Operations)

- Tel:(60) 3 7890 6399

- 9:00am - 6:00pm (Monday - Friday)

9:00am - 1:00pm (Saturday) - Technical Inquiry

How can we improve?

How can we improve?

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Customer Privacy Policy

Thank you for your cooperation.

While we are not able to respond directly to comments submitted in this form, the information will be reviewed for future improvement.

Please use the inquiry form.

Customer Privacy Policy